“The Little Prince” eriversioon valmis ajaloolises kõrgtrükitehnoloogias ja masinatega, mis on pärit 20. sajandist või vanemadki. Loe lähemalt, kuidas me seda tegime.

LADUMINE JA KORREKTUUR (ning ladumine ja korrektuur)

Kui raamatu kujundus ja küljendus oli valmis ja keeletoimetaja poolt üle kontrollitud, hakkas meie trükimeister Jörgen raamatuteksti laduma. Selleks kasutas ta realadumismasinat ehk linotüüpi.

Linotüüp, mis leiutati 1880tel, oli üks kõige olulisem masin 20. sajandi trükikojas. Enne linotüübi leiutamist tuli raamatute ja ajalehtede tekstid käsitsi metalltähtedest laduda. Realadumismasinaga muutus see töö palju kiiremaks: masinladuja lihtsalt toksib teksti klaviatuuril sisse, masin laob selle põhjal matriitsidest tekstirea ning valab sinna sulametalli. Tulemuseks on värskelt valatud tinarida, mida saab kasutada trükkimiseks.

Tõele au andes… Masin, mida meie ridade valamiseks kasutasime, ei olnud mitte päris Linotüüp, vaid Nõukogude Liidus toodetud koopia, N-14. Tänaseks päevaks seisab meil TYPAS Nõukogude N-14 kõrval ka päris Saks Linotüüp – mõlemad töötavad ühtemoodi hästi.

Selleks, et laduda kokku “The Little Prince” raamatu tekstiread, pidime kasutada paarsada kilogrammi metalli. Vaata videost järgi, kuidas meie trükimeister Jörgen realadumismasinas seda teeb:

Kui tekstiread said valmis valatud, tegime neist proovitõmmised, millele keeletoimetaja veel korrektuuri pidi tegema, leidmaks üles trüki- ja muud vead. Kui korrektuur tehtud, valas Jörgen kõik vigased read uuesti. Vahel tähendas see seda, et uuesti tuli laduda terve lõik ning vahel tekkisid paranduste tegemisel uued vead. Seetõttu oli vaja ladumise > proovitrüki > korrektuuri > ladumise ringi mitu-mitu korda korrata enne kui kõik vead said üles leitud ja parandatud.

Kui raamatu põhiteksti ladusime realadumismasinaga, siis raamatu pealkirja ning pühendused (kinkeversioonidele) ladusime käsitsi. Selleks kasutasime Admirali kirjatüüpi oma käsilao kollektsioonist. Käsiladumine on ajakulukas ning laduja peab seda tööd tegema peegelpildis. Tinatähed ise on samuti peegelpildis, kuna trükkides tekib paberile peegelpildis kujutis.

MASINASSE PANEMINE, KATMIK, ELVASTAMINE, VIIMANE PROOVITRÜKK JA TRÜKKIMINE

Kui kogu laotud raamatutekst oli kontrollitud ja vead parandatud, saime hakata raamatulehekülgi tekstiridadest, illustratsioonidest, peatüki ja lehekülje numbritest kokku panema. Seejärel sai valmis vormistatud leheküljed tõsta masinasse. Kuna pidime trükkima 16 lehekülge korraga suurele paberipoognale, tuli leheküljevormid masinasse panna sellisel viisil, et pärast poognate kokkuvoltimist ja köitmist jookseksid leheküljed raamatus õiges järjekorras.

Sisupoognate trükkimiseks kasutasime oma suurimat, raskemat, valjemat ja sinisemat masinat: Victoria Polygraph V 1040-2. Tegemist on stopp-silinderpressiga, mis ehitati Saksamaal 1980tel ning see kaalub 8,5 tonni. Nagu silinderpressi nimi viitab, on selle masina kõige olulisem osa raske metallist silinder. Silinder rullib üle laotud lehekülgede justkui taignarull, trükkides värviga kaetud teksti ja illustratsiooni paberile. Ühtlase tulemuse saamiseks tuleb silinder esmalt katta pehme ja painduva materjaliga – kas kummi, riide või paberiga. Seda osa kutsutakse katmikuks.

Kui katmik tehtud, tuleb survet elvastuse ja katmiku abil ühtlustada, et kõik leheküljed ühtlaselt hästi trükiks. Pärast elvastamist sai trükkal Jörgen teha lõpliku proovitõmmise, mille vaatas veel üle toimetaja. Kui kõik sai heaks kiidetud, olid esimesed 16 lehekülge trükkimiseks valmis. Vaata Victoriaga trükkimist siit videost:

Trükkimiseks on vaja kahte inimest: trükkalit, kes opereerib masinat ning vastuvõtjat, kes kontrollib trükitud poognate kvaliteeti. Esimesest 16 leheküljest trükkisime ca 300 koopiat enne kui saime masina tühjaks tõsta ning hakata otsast pihta lehekülgedega 17-32, et alustada taaskord lehekülgede masinasse paigutamise, katmiku meisterdamise, elvastamise ja alles seejärel trükkimisega. Kokku tegime seda kuus korda.

ÜMBRISPABERITE TRÜKKIMINE

Kuna raamatu sisulehed trükkisime must-valgena, tahtsime teha ümbrispaberid toredalt mitmevärvilised. Meie vanade masinate puhul tähendas see seda, et pidime trükkima iga värvi – kollase, beeži, musta ja sinise – eraldi. Trükkal Jörgen pidi siinkohal olema eriti täpne, et iga värv täpselt õigesse kohta trükiks.

EESLEHTEDE TRÜKKIMINE

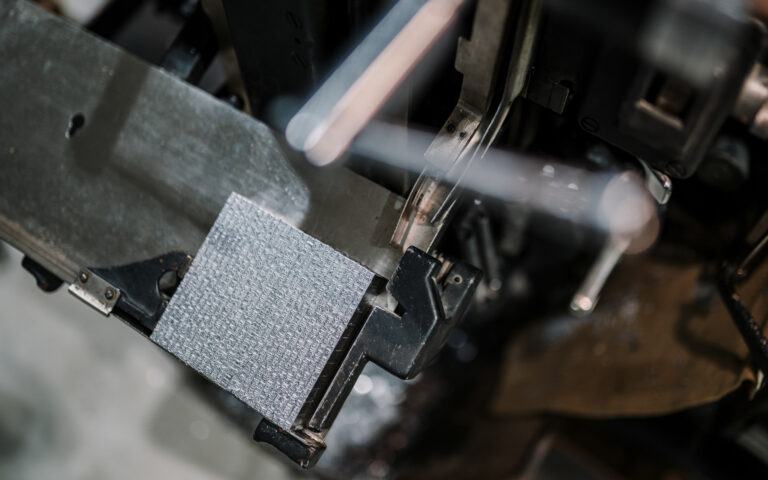

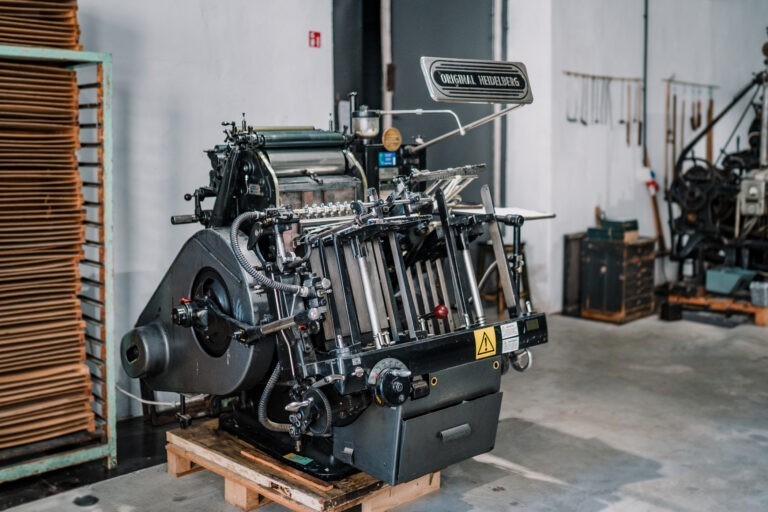

Eeslehed on kõvakaanelise raamatu esimesed ja viimased lehed, mille abil raamatu sisuplokk kaante küljes püsib. Meie plaan oli trükkida eeslehtedele kollane tähtede ja planeetidega muster. Selleks kasutasime uuesti klišeesid, mida sisupoognate trükkimisel olime kasutanud peatükkide eraldamiseks. Eeslehede trükkisime hoopis teise trükimasinaga: Heidelberg T tiigelpressiga.

KÕVAKAANED

Esimesed 150 koopiat raamatust (collector’s edition, gift edition ja hands-on edition) köitsime käsitsi TYPAs. Nende raamatute kaaned trükkisime kohapeal siiditrükitehnikas. Need täiesti käsitööversioonina valminud raamatud on ka palju kallimad.

Ülejäänud 200 koopiat (letterpress edition) saatsime Greifi trükikotta lõpetamisele, kus neil on palju kaasaegsemad võimalused raamatute köitmiseks ja fooliumtrükiks. Letterpress edition’id said kõvakaantele fooliumtrükis pildid: